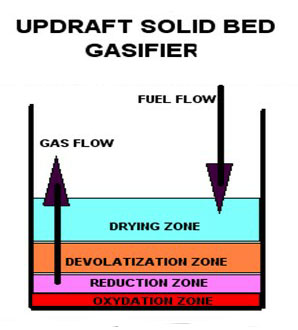

Gasification

Krann Engineering Limited designs biomass fuel energy systems using updraft gasifier

as a heat source.

Krann systems are offered in range of 1MW (3MMBTU/hr) up to 22MW (75MMBTU/hr) net

output from a single cell. For lower output range they they are offered as portable,

skid-mounted units.

Although the theory of updraft gasification is well understood, the Krann system

employs novel features allowing for a higher output rate from the gasifier cell as

compared to other gasifiers systems. Thus, it provides a very economical value for

the end-user.

The Krann gasification process allows the gasification of fuels at high moisture

content (up to 60-65%) since the water does not enter the gasification zones. This

process is self sustaining and is controlled by adjusting the fuel and air flow. At

the end of the gasification sequence the fuel is entirely converted to clean syngas

and ash. The syngas typically enters the secondary chamber where the combustion is

completed by adding a controlled amount of the secondary air. Since the combustion

takes place inside the fuel pile and the ashes are contained in the pile, the resulting

gases contain much less particulate than those formed by conventional wood burning

systems. Also, the production of pollutants, notably CO and NOx, is much lower compared

to conventional wood burning systems. Furthermore, there is no visible opacity even

with very wet fuels. The main advantages of the Krann gasifier include simplicity

because it has few moving parts. Additionally, the high char burn-out and efficient

heat transfer between the syngas and fuel particles in the pile lead to low syngas

exit temperatures and elevated equipment efficiency.

The syngas can also be burned directly in the boiler similarly to natural gas combustion.

The combustion temperature is typically controlled at 800C – 1200C depending upon

the fuel moisture content and customer requirements. The flue gas is forced through

the heat transfer device (e.g. boiler or dryer) by the ID fan in similar fashion,

as in conventional wood combustion systems.

The Krann combustion system is specifically optimized for high output rates from

a relatively small furnace volume. Therefore, the system cost is efficient compared

to conventional biomass burning systems or other gasifiers.

The system can be used in a variety of applications such as providing heat for boilers,

kilns, dryers, greenhouses, etc. The system is fully automated and consists of wood

storage, gasifier, syngas burner, heat absorbing equipment and exhaust stack, typically

all housed in one building.

Fuels:

- Sawmill wood waste e.g. hog fuel, shavings

- Demolition wood

- Refuse Derived Fuels (RDF)

- Agricultural waste e.g. straw, flax, rice husks

- Wood grindings, pellets etc

- Sludge

- Combination of above

General Benefits:

- ability to burn unprocessed biomass up to 60% moisture content

- much lower emission than conventional biomass burning system

- less ash deposit on boiler tube surfaces

- small footprint

- able to operate with fuel feed interruptions up to 30 minutes

- automatic ash discharge

- sand, dirt need not be removed from fuel

- fully automated operation with low degree of maintenance and supervision

- very fast response to heat demand changes

- robust fuel feed system

- low electrical power bill

- high turndown ratio

- lower price than comparable biomass systems